A pre-coated metal has the highest value among all cold-rolled steel products. Produced by printing or baking paints onto the surface of cold-rolled steel or GI or GL sheets, pre-coated metal features a wide range of colors and patterns which are commonly used to make the exterior of buildings and consumer electronics products look more polished and sophisticated. Depending on the specific utility of each product, a vast variety of features are available including pollution resistance and anti-bacterial quality.

Product Type

· Polyester/silicon coated steel: Has excellent weather resistance; widely used as a dry material

· Hi-Polymer (Hi-Polymer polyester coated steel): Used for deep drawing process that requires particularly high flexibility, as well as consumer electronics products including refrigerators, VCR’s, microwave ovens

· Laminated steel: A product coated with a film that features a vast diversity of fine colors and patterns

· PVDF: A PVDF (specialty plastic material) coated steel sheet with ultra weather-resistance and superb anti-corrosion properties

· Emboss: A high-end pre-coated steel plate treated with embossing process to give 3-D quality

· Green Board: A pre-coated steel sheet used in the construction of bulletin boards

· Static-eliminated steel: A pre-coated sheet with anti-dust properties as well as anti-static and fireproof properties, which is used for clean rooms

· Anti-bacterial steel: A multi-functional sheet coated with a film that contains silver nanoparticles known for their anti-bacterial, sterilizing and odor-resistant properties, which is also capable of protecting against UV rays and electromagnetic radiation and ensuring electric static elimination and insulation.

■Paint Coating Material

Products | Front Side | Reverse Side |

Primer Coating | Finish Coating |

Polyester Coated | Epoxy Primer / Polyurethane Primer (PU) | Regular Polyester (PE) | Service Coating |

Silicon Modified Polyester Coated | Silicon Modified Polyester (SMP) |

Polyvinylidene Floride Coated | Polyvinylidene Floride (PVDF) |

Super Low Gloss Polyester Coated | Super Modified Polyester |

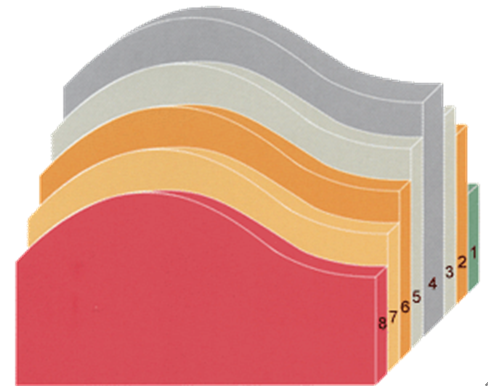

■SECTIONAL VIEWS OF PAINT COATING

|

|

|

|

1. Service Coating |

|

2. Chemical Pretreatment |

|

3. Zn/Galvalume Coating |

|

4. Cold Rolled Strip |

|

5. Zn/Galvalume Coating |

|

6. Chemical Pretreatment |

|

7. Primer Coating |

|

8. Finish Coating |

|

■ Performance

Perfor- mance | Primer | 7 microns |

Top coat | 20-25microns |

Primer+Back coat | 7-25microns |

Color | AS per RAL code/customer's requirement |

Gloss | Matt 35% (+/- 5%)/semi-gloss 60%, (+/- 5%) high gloss > 70% |

Pencil hardness | H (min.) |

Impact test (in Joules) | As per JIS G 3312 |

Salt spray test | 500-1000 hrs |

Adhesion test (cross-hatch) | 100% |

Erichsen cupping test | 7mm |

Humidity test | 1000 hrs |

T-Bend test (T = substrate thickness) | 2 T (no tape loss) |

Solvent rub test (MEK- double rub) | >50 rubs |

Chemical resistance 5% NAOH, 5% H2SO4 | No blistering, discolouration and softening of paint film. |

Max. operating temp. | 120 °C |

Consumer electronic product bodies (refrigerator, air conditioner, etc.), construction panels, roofing, doors, shelters, etc.